OpenAI and Foxconn announced a multibillion-dollar partnership on November 20 to manufacture AI data center hardware in the United States. Foxconn will invest up to $5 billion to build complete AI server racks at industrial scale—targeting 2,000 racks per week by 2026. At an average of $3.9 million per rack, that’s $7.8 billion in weekly production capacity. This isn’t a marginal upgrade. It’s infrastructure at a scale that could reshape who gets to build AI products.

The timing matters. Companies building AI face 12 to 18 month lead times for data center equipment. GPUs are backordered for months. Power systems, cooling infrastructure, networking—everything’s a bottleneck. Foxconn’s Wisconsin facility alone will see $569 million in investment and add 1,374 jobs. The partnership targets complete rack systems: power, cooling, networking, cabling, all integrated and ready to deploy.

What’s Actually Being Built

This isn’t about GPUs. Foxconn and OpenAI are co-designing complete AI server racks—the physical infrastructure that houses hundreds of GPUs, connects them with high-bandwidth networking, keeps them cool, and delivers the massive power they require. Training large AI models demands fleets of GPUs distributed across many machines. You can’t fit GPT-scale training on a single server. You need racks. Lots of them.

The partnership will develop multiple generations of rack designs in parallel, letting OpenAI stay ahead of rapidly evolving AI architectures. OpenAI gets early access to evaluate systems and an option to purchase, while Foxconn scales U.S. manufacturing capacity. By 2026, that’s 2,000 racks rolling out weekly from American facilities.

The Infrastructure Crisis No One’s Talking About

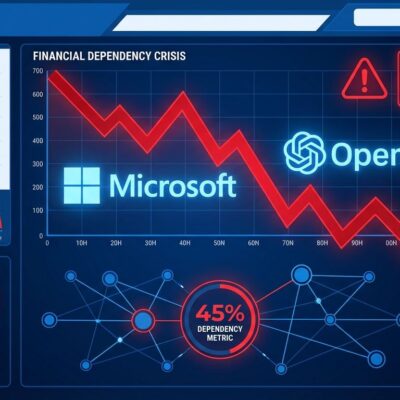

Here’s what developers face right now: Nvidia’s high-end GPUs are backordered months in advance. Equipment procurement—transformers, cooling systems, switchgear—takes 12 to 18 months. The GPU rental market is exploding from $3.34 billion in 2023 to a projected $33.91 billion by 2032 because access is that constrained. Sixty-four percent of tech companies cite GPU access as a key challenge. And here’s the kicker: 92 percent of data center operators now say power capacity—not GPU availability—is their primary constraint.

The industry is projected to spend $375 billion on AI infrastructure in 2025, a 67 percent surge year over year. By 2030, the industry needs $5.2 trillion invested in data centers to meet AI demand alone. A single large-scale AI data center can cost $7 billion. OpenAI just signed a $38 billion, seven-year cloud computing deal with AWS. The scale isn’t just big. It’s bonkers.

What This Means for Developers

More rack availability should translate to shorter deployment times. If you’re building AI products that need serious infrastructure—training custom models, running large-scale inference, building agentic systems—you’ve been stuck waiting. The bottleneck has been real. Domestic U.S. manufacturing also reduces geopolitical risk. Taiwan produces 90 percent of the world’s most advanced logic chips. A single trade dispute or geopolitical incident could cripple global AI infrastructure production. Foxconn’s U.S. facilities diversify that risk.

Will this solve the infrastructure problem? No. Power and cooling constraints remain. But it addresses the immediate rack availability bottleneck while longer-term chip fabrication investments (Intel’s $100 billion plan, TSMC’s $65 billion U.S. expansion) come online over the next few years. The Foxconn-OpenAI partnership targets 2026—faster than new semiconductor fabs can ramp.

The Bigger Picture: Who Gets to Build AI

This is part of a larger infrastructure arms race. Intel, TSMC, and now Foxconn are all making massive U.S. manufacturing bets. The difference: Intel and TSMC are building chip fabs with multi-year timelines. Foxconn is building rack systems with an 18-month horizon. That addresses the problem developers face today, not three years from now.

Infrastructure availability determines who can build AI products at scale. If you can’t access GPUs, you can’t train competitive models. If you can’t deploy inference infrastructure, you can’t serve users. The companies solving infrastructure bottlenecks aren’t just improving supply chains—they’re deciding who participates in the AI economy. OpenAI clearly understands this. By partnering with the world’s largest contract manufacturer, they’re securing access while the rest of the industry fights over constrained capacity.

The Foxconn-OpenAI deal won’t eliminate infrastructure constraints. But it signals how critical these constraints have become—and how much capital is flowing to solve them. If you’re building AI products, infrastructure availability isn’t an operational detail. It’s a strategic moat. And right now, that moat is being built in Wisconsin.