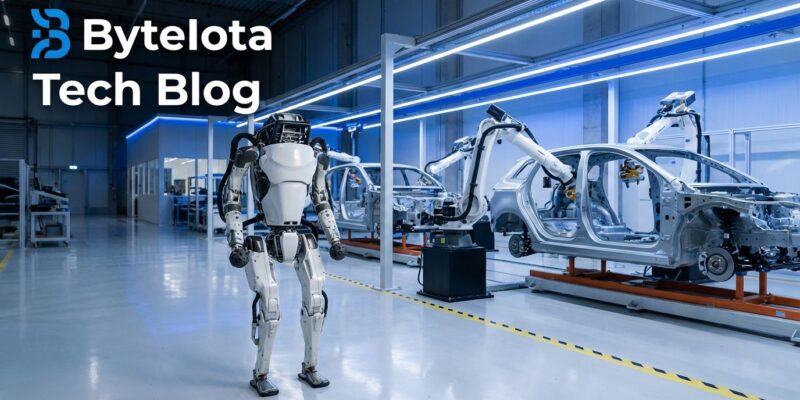

Boston Dynamics’ Atlas robot has been doing backflips since 2017. Now it’s attempting something far more difficult: real factory work. At CES 2026, Hyundai announced that 30,000 Atlas humanoid robots will reach production by 2028, with deployment starting at their $7.6 billion Georgia EV factory. This is the moment humanoid robotics moves from viral demos to actual production—if it doesn’t stumble.

Production Starts Now, Deployment in 2028

The announcement was specific. Production begins immediately at Boston Dynamics’ Boston headquarters, scaling to 30,000 units annually by 2028. First deployment: Hyundai’s Georgia Metaplant in Ellabell, a 2,284-acre facility with 16 million square feet of factory floor space currently producing the Ioniq 5 and Ioniq 9 EVs.

The robots will start with parts sequencing in 2028—simple, repetitive tasks with proven safety benefits. By 2030, they graduate to component assembly and heavy lifting. It’s a cautious rollout, which is either smart risk management or a sign that the technology isn’t as ready as the viral videos suggest.

Google’s AI Meets Boston Dynamics’ Hardware

Hardware alone doesn’t make a factory robot. Boston Dynamics partnered with Google DeepMind to integrate Gemini Robotics AI foundation models into Atlas. This gives the robot environmental perception, task reasoning, tool use capabilities, and human interaction protocols—the cognitive layer needed to adapt to unpredictable factory conditions.

The partnership reunites Boston Dynamics with Google, its former owner from 2013 to 2017. It’s also a strategic differentiator: Tesla Optimus uses in-house AI, Figure AI partners with OpenAI, but Atlas gets Google’s AI leadership combined with Boston Dynamics’ 13 years of hardware development. That’s a formidable stack—on paper.

The Atlas specs back it up: 56 degrees of freedom (versus Figure AI’s 35), 110-pound lifting capacity, dual battery packs with autonomous self-swapping in three minutes, and weatherproof operation from -4°F to 104°F. It’s built for factories, not demos.

The Humanoid Robot Race Heats Up

Atlas isn’t alone. Tesla’s Optimus targets 1 million units by end of 2026 with a $20,000-$30,000 price point, leveraging automotive supply chain economies of scale. But reality check: Tesla’s 2025 goal produced hundreds of units, not thousands, and a leaked Miami demo showed the robot falling. Execution gaps persist.

Figure AI takes a different approach—100,000 units over four years, starting with home and factory pilots in 2026. Figure 03 completed 11 months of real-world testing at BMW factories, but its price exceeds $100,000, significantly higher than Tesla’s target. The market sizing: 50,000 to 100,000 humanoids expected to deploy in 2026 across all vendors, with manufacturing and fulfillment leading adoption.

Three companies, three strategies: Tesla bets on price and scale, Figure AI on proven deployment, Boston Dynamics on capability and industrial focus. No clear winner yet, but whoever cracks factory reliability at scale wins the market.

30,000 Robots, How Many Jobs?

Studies show one robot added to a geographic area displaces six workers. Linear math puts 30,000 robots at 180,000 jobs displaced, though that’s simplistic. Hyundai positions Atlas for “dangerous” and repetitive tasks—parts sequencing, heavy lifting, work humans shouldn’t or don’t want to do.

The counterargument: manufacturing faces labor shortages from aging workforces and reshoring efforts. Robots fill gaps, and new roles emerge—robot trainers, fleet managers, maintenance specialists. Automotive manufacturing automated decades ago, creating different jobs, not zero jobs. But displaced workers face real reskilling challenges, and not everyone becomes a robot supervisor.

The debate isn’t new. What’s new is the scale: 30,000 units makes the impact tangible, not theoretical.

Can Demo Magic Scale?

Here’s the reality check. Boston Dynamics has produced stunning demos for years—backflips in 2017, parkour in 2018, dancing robots in 2020. Viral gold, zero products. The question: can controlled demo environments translate to unpredictable factory floors with spills, lighting changes, and chaos?

Reasons for optimism: Hyundai owns 80% of Boston Dynamics (aligned incentives, no customer acquisition needed), Google DeepMind provides world-class AI, production already started, and the cautious rollout (simple tasks first) signals realism. Reasons for skepticism: two years to 30,000 units annually is aggressive, Tesla’s Optimus missed 2025 targets significantly, and cost per unit hasn’t been disclosed. Is the ROI competitive with human labor at scale?

Success in 2028 means robots reliably perform parts sequencing without constant human supervision. Failure means “production” stays limited to controlled test environments while the real factory floor remains human-operated. Boston Dynamics has the best shot—proven hardware, Google AI, Hyundai backing. But demo magic has fooled us before. 2028 will tell the real story.