The semiconductor industry is projected to hit $701 billion in 2025, marking 11.2% year-over-year growth fueled by a fundamental market shift: artificial intelligence has displaced automotive as the top revenue driver for the first time in industry history. Furthermore, AI chips alone will exceed $150 billion in sales this year, transforming priorities across the entire semiconductor ecosystem.

However, this isn’t just growth—it’s a reordering of the industry’s economic foundation. Moreover, while the numbers look impressive, the path to delivering on this AI-driven demand faces serious constraints that could determine whether the boom sustains or stalls.

AI Chips Overtake Automotive as Industry’s #1 Revenue Driver

For years, automotive chips drove semiconductor revenue growth. That era is over. Generative AI chips surged from $125 billion in 2024 to a projected $150 billion-plus in 2025, outpacing every other segment. Consequently, when you factor in AI-related components—GPUs, CPUs, high-bandwidth memory (HBM), DRAM, and advanced packaging—the AI ecosystem represents the industry’s single largest revenue source.

This shift is visible in manufacturing equipment spending, which hit a record $125.5 billion in 2025 (up 7.4% year-over-year), according to SEMI. That equipment isn’t being built for smartphones or laptops—traditional PC and mobile markets remain muted. Instead, it’s going toward data center capacity to meet insatiable AI compute demand.

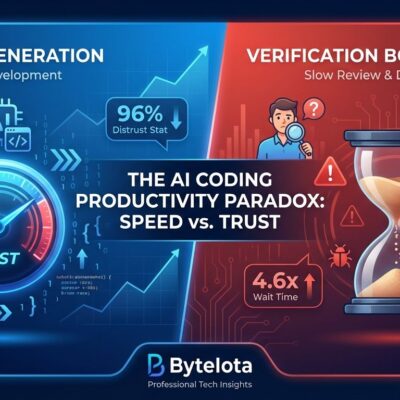

For developers, this translates directly to cloud GPU pricing and availability. AI chip supply constraints aren’t going away soon, which means high costs for training and inference workloads. Understanding semiconductor economics isn’t just industry trivia—it’s the foundation beneath your infrastructure costs.

The Talent Crisis: 1 Million Workers Needed, Half May Go Unfilled

Here’s the constraint nobody wants to talk about: the semiconductor industry needs to add 1 million skilled workers globally by 2030—over 100,000 annually—but current degree completion rates suggest 58% of US jobs will go unfilled.

The numbers get worse in 2025. Specifically, annual demand for engineers is doubling from 9,000 to 17,000, while technician demand jumps from 7,000 to 14,000. Meanwhile, the industry is expanding capacity through massive capital investments (more on that below), but it can’t staff the fabs it’s building.

The root causes are structural. One-third of US semiconductor workers are 55 or older, approaching retirement. Similarly, electrical engineering and computer science enrollment has been declining for years—Germany saw a 6.5% drop in STEM students in 2021 alone. Additionally, skill requirements are evolving: AI and machine learning expertise now matters more than traditional systems architecture knowledge.

This creates a paradox. The industry is betting $185 billion in capital expenditure on expanding capacity by 7% in 2025, but without workers to operate new fabs, that capacity won’t materialize. However, for tech professionals, this represents opportunity—115,000 new US semiconductor jobs by 2030, many requiring software and embedded programming skills that overlap with traditional dev work.

CHIPS Act Fuels $185B Capex Wave and US Manufacturing Expansion

The CHIPS and Science Act’s $39 billion in funding has catalyzed 90 new US semiconductor projects expected to triple domestic chipmaking capacity by 2032 and create over 500,000 jobs. Consequently, the industry is backing this with $185 billion in capital expenditure for 2025 alone.

The major projects reshaping US semiconductor geography include:

TSMC Arizona: $6.6 billion in CHIPS Act funding supporting a $165 billion total investment (expanded from $65 billion in March 2025). Furthermore, three leading-edge fabs in Phoenix will produce one-third of TSMC’s most advanced chips domestically, starting with 4nm production in the first half of 2025. This creates 6,000 direct manufacturing jobs plus over 20,000 construction positions.

Samsung Texas: $4.745 billion in CHIPS funding toward a $37 billion investment covering two new logic fabs and an R&D facility in Taylor, plus an Austin expansion opening in 2026.

Texas Instruments: A $60 billion megaproject spanning Sherman, Richardson (Texas), and Lehi (Utah), with the Sherman facility reaching full production by the end of 2025.

Additionally, Nvidia’s $500 billion commitment (announced April 2025) to manufacture Blackwell chips across Arizona and Texas makes the geographic shift clear: Phoenix and Austin are emerging as semiconductor epicenters comparable to traditional Silicon Valley in scope and economic impact.

For developers, this means new tech ecosystems forming outside the Bay Area, with different cost-of-living economics and career trajectories. Moreover, it also signals supply chain diversification away from Asia-heavy concentration, though that transition brings its own complications.

Geopolitical Uncertainty Threatens Long-Term Stability

Here’s where the optimism hits reality: semiconductor fabs require 3-5 year construction timelines and multi-billion dollar investments, but the Trump administration has threatened tariffs up to 300% on chip imports while simultaneously criticizing the CHIPS Act as “unnecessary subsidization” and pledging to renegotiate awards downward.

This policy whiplash creates problems. Specifically, the CHIPS Program Office was transferred to a new “US Investment Accelerator” with a mandate to get a “better deal for the American people”—bureaucratic language for cutting previously committed funding. Nevertheless, companies like TSMC are hedging by expanding US investments (hence the March 2025 increase to $165 billion), but they’re also watching whether the policy foundation supporting these projects will hold.

The broader geopolitical picture is fragmenting. The US-China chip war has moved from trade friction to outright technological iron curtain, with the once-integrated global supply chain splitting into regionalized blocs. Meanwhile, Europe faces its own challenges with a projected 100,000+ engineer shortage by 2030 while Asia-Pacific needs 200,000+ workers.

Quote from industry analysis: “The era of seamlessly integrated global semiconductor supply chain is decisively over.” That statement, from multiple trade analysts, isn’t hyperbole. Consequently, developers building international products need to account for regional supply chain constraints affecting component availability and costs going forward.

What This Means for Developers and Tech Professionals

The semiconductor industry’s AI-driven boom creates tangible impacts for software developers and tech professionals:

Cloud costs aren’t coming down. AI chip demand will keep GPU pricing elevated. Furthermore, supply constraints from talent shortages and geopolitical fragmentation mean high inference and training costs persist. Budget accordingly.

Career opportunities are real. The 115,000 new US semiconductor jobs by 2030 include software roles—embedded programming, AI-assisted chip design, and manufacturing automation. Therefore, these aren’t just hardware engineering positions.

Geographic diversification matters. Phoenix, Austin, and Taylor (Texas) are becoming semiconductor hubs with growing tech ecosystems. Moreover, they offer lower cost of living compared to Bay Area, with similar growth trajectories in specialized areas.

Understanding chip constraints improves software design. Knowing why GPUs are expensive, why certain architectures dominate, and where manufacturing bottlenecks exist helps you make better technology decisions.

The $701 billion semiconductor market in 2025 represents the foundation beneath every AI application, cloud service, and data center operation. Ultimately, the industry’s ability to deliver on AI-driven demand—or fail to do so due to talent shortages and policy uncertainty—will shape tech costs and capabilities for the next decade. Developers who understand these dynamics will make better architecture decisions and spot career opportunities others miss.