Intel’s Core Ultra Series 3 processors—the first chips built on the company’s breakthrough 18A process—began shipping globally today, January 27, 2026. These are the first Intel 18A products to reach consumers, marking the most advanced semiconductor ever manufactured in the United States. This launch is Intel’s make-or-break moment to prove US chip manufacturing can compete with Taiwan’s TSMC after years of decline.

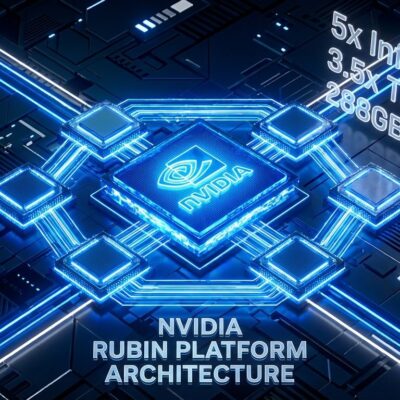

The 18A Breakthrough: RibbonFET Meets PowerVia

Intel 18A (18-angstrom) combines two fundamental innovations. RibbonFET, Intel’s implementation of gate-all-around transistors, wraps the gate completely around the channel—a significant leap over FinFET’s three-sided approach. PowerVia moves power delivery to the chip’s backside, separating it from signal routing for the first time in production chips.

The results: 60% better multithread performance, 77% faster gaming versus previous-generation Lunar Lake, and up to 27 hours of battery life in Netflix streaming tests. Intel’s Arc B390 integrated GPU delivers Cyberpunk 2077 at 81 fps (1080p Low), jumping to 169 fps with upscaling enabled—performance Intel claims rivals Nvidia’s GeForce RTX 4050 laptop GPUs.

Why This Matters: US Semiconductor Independence

Currently, 92% of advanced chips come from Taiwan and South Korea. If China invades Taiwan or blockades TSMC, global chip supply collapses. Intel 18A provides critical US backup manufacturing capability, backed by $7.86 billion in CHIPS Act funding and an additional $8.9 billion equity stake from the Trump Administration.

Intel has committed over $100 billion to US manufacturing expansion across Arizona, Ohio, Oregon, and New Mexico. The 18A launch validates this massive bet. Success strengthens US tech independence. Failure ends American advanced chipmaking ambitions.

The Foundry Credibility Test

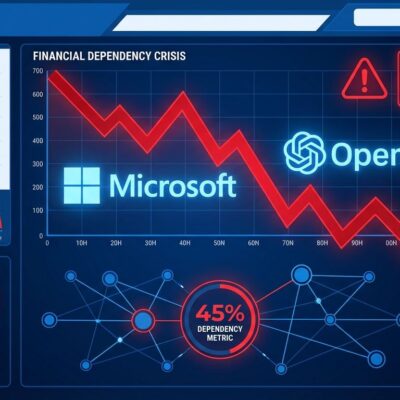

Intel’s bigger play isn’t selling its own chips—it’s becoming a credible alternative to TSMC for external customers. The IDM 2.0 strategy aims to turn Intel into the world’s second-largest foundry, behind TSMC but ahead of Samsung. Intel has onboarded Microsoft, Tesla, and Qualcomm for packaging services, but no major customer has committed to 18A wafer production yet.

Nvidia paused 18A wafer testing in late 2025 due to yield concerns. Intel needs 70-80% yields to be profitable. TSMC controls 75% of the leading-edge foundry market with proven yields and customer trust. As one Hacker News developer put it: “Can’t reach high yields without a customer, but customers only want to sign up if yields and future deliveries are guaranteed.”

Intel delivered on its technical promise—”five nodes in four years” under CEO Pat Gelsinger. But the graveyard of failed Intel Foundry customers over the past 15 years looms large. The 18A launch is Intel’s last chance to prove foundry credibility.

Beyond PCs: Embedded and Industrial IoT

For the first time, Intel has certified Core Ultra Series 3 processors for embedded and industrial use cases—robotics, smart cities, automation, and healthcare. This opens revenue streams beyond the declining PC market into high-growth edge computing segments where TSMC and Qualcomm currently dominate.

The Reality Check

Intel proved critics wrong by delivering 18A on time. Revenue has dropped from $79 billion (2021) to $53.1 billion (2024), and gross margins have collapsed from 62% to 32.7%. The foundry division has posted multibillion-dollar operating losses for three straight years. Profitability isn’t expected until 2027 or later.

But here’s the uncomfortable truth: the tech industry needs Intel to succeed. Not because they’re the best—TSMC still leads on yields and customer trust—but because TSMC concentration risk is too high. Intel 18A may not be perfect, but it’s the only viable path to supply chain diversification.

The question isn’t whether Intel can compete technically anymore. The 18A launch proves they can. The real test: Will customers trust Intel Foundry with their designs? US semiconductor independence rides on the answer.