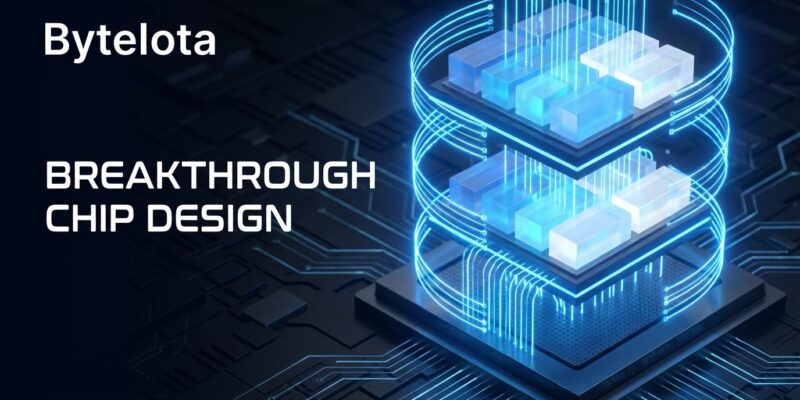

Researchers at Stanford, Carnegie Mellon, MIT, and the University of Pennsylvania have achieved a 4× performance breakthrough in AI chip design by stacking memory and computing elements vertically instead of side-by-side. The monolithic 3D chip, manufactured at SkyWater Technology’s U.S. foundry and presented at the IEEE International Electron Devices Meeting in December 2025, attacks AI’s fundamental bottleneck: not compute power, but the time wasted shuttling data between memory and processors.

The Memory Wall Problem

The breakthrough addresses what researchers call the “memory wall” – the growing performance gap between how fast processors compute and how quickly they can access data. Moving data from memory to processors consumes up to 500 times more energy than the actual computation. Every inference through a large language model requires loading billions of weights from memory, and that data movement has become the limiting factor.

Over the past 20 years, compute performance scaled 3× every two years while memory bandwidth only scaled 1.6×. The gap keeps widening. The von Neumann bottleneck – where memory and processors sit physically separated, forcing data to travel back and forth across long pathways – wasn’t designed for AI workloads.

NVIDIA’s H100, currently the top AI training chip, delivers 3.35 TB/s of memory bandwidth with HBM3 memory. That’s nearly double the previous generation A100’s 2 TB/s. Yet the high-bandwidth memory alone accounts for over 50% of the H100’s cost, and memory bandwidth remains the constraint. The chip industry kept widening the pipe, but the fundamental distance problem remained unsolved.

Vertical Stacking Changes the Game

The research team’s solution stacks memory layers directly above and below computing elements using monolithic 3D integration. Instead of data traveling horizontally across the chip like traffic on a congested highway, it moves vertically through short connections – like taking an elevator between floors instead of walking across a sprawling campus.

This isn’t the same as “hybrid bonding,” where separately manufactured chips are joined together with through-silicon vias. Monolithic 3D integration builds active device layers directly on top of each other during fabrication, achieving the densest 3D chip wiring ever demonstrated in a commercial foundry. The vertical approach fundamentally eliminates distance rather than just optimizing around it.

According to the announcement, early hardware tests show the prototype outperforms comparable 2D chips by roughly 4×. Simulations with additional tiers project up to 12× improvement on real AI workloads, including those derived from Meta’s open-source LLaMA model. This is the first time a monolithic 3D chip has shown clear performance gains and been manufactured in a commercial U.S. foundry.

Built in a U.S. Commercial Foundry

The chip was fabricated at SkyWater Technology’s foundry in Bloomington, Minnesota. That manufacturing location matters. Many research breakthroughs remain stuck in university labs because they require specialized equipment or processes that can’t scale commercially. Building this chip in an existing commercial foundry proves the design isn’t just theoretically sound – it’s manufacturable with current infrastructure.

The U.S. location also carries supply chain implications. Domestic semiconductor manufacturing has become a strategic priority, backed by the CHIPS Act. A successful 3D integration technology built in a U.S. foundry strengthens domestic chip production capabilities at a time when AI hardware demand is exploding.

Timeline and Industry Impact

This is research with validated hardware results, not a product announcement. The typical semiconductor research-to-production timeline runs 3-5 years. Expect process refinement, scaling to larger chips, and partnerships with chip designers before seeing commercial products. Realistically, 2027-2029 is the earliest window for production-ready chips based on this technology.

If the technology scales economically, it could challenge NVIDIA’s estimated 80-90% market share in AI training chips. Current competitors – AMD, Intel, Google’s TPU, Amazon’s Trainium – all face the same memory wall. A fundamentally different architectural approach could enable leapfrogging the current generation rather than competing on incremental bandwidth improvements.

For AI developers, the implications run deeper than faster training. The memory wall currently limits model size, forces aggressive optimization, and drives up energy costs. A 4-12× improvement in data movement speed could enable models and applications that are currently impractical. Larger models without proportional slowdown. Faster iteration cycles. Lower energy consumption for the same workload.

The Right Problem to Solve

The semiconductor industry spent the past decade scaling compute. TPUs, GPUs, specialized AI accelerators – all focused on adding more processing power. But AI workloads increasingly spend more time waiting for data than computing. This research attacks the actual bottleneck.

Whether this specific design becomes the dominant approach or spurs competing 3D architectures, the direction is clear. Future AI chips will be built vertically, not horizontally. The memory wall won’t fall overnight, but the research collaboration between Stanford, CMU, MIT, and Penn demonstrates that it can be broken.